Application SolutionsConstruction

CLAF® fabric provides practical answers to tough challenges in the construction industry worldwide. Construction material manufacturers use CLAF® fabric as reinforcement in a variety of construction-related products, such as housewrap, roofing composites and radiant barriers. Additional benefits of construction materials with CLAF® mesh fabric include:

- High tear resistance

- Increased burst strength

- Breathability

- Drainage properties

- Low elongation

- Excellent dimensional stability

ANCI, Inc. Housewrap

ANCI, Inc. has developed a comprehensive family of Energy Efficient Building Envelope Products which not only addresses the needs of any wall system and design, but does so with an efficient combination of functionality into one single application step.

The CLAF® fabric based family of building envelope products combines superior performance features in one application process. This product range allows builders and architects to choose the proper moisture vapor transmission rate (MVTR or Perms); industry leading drainage properties on all products, and superior water resistance or water head - all in one family of products. When properly installed all products are certified to be used as an Air Barrier Material as a stand-alone product or within an Air Barrier system.

ANCI Housewrap products are the only commercially available Drainage Plane Air Barrier Materials (ASTM E - 2273) available in high, medium and low breathability versions to meet the needs of the building envelope design.

Marketed through select distributors, CLAF®-based housewrap products are performance-proven with more than 20 years of manufacture and installation on commercial and residential properties.

CLAF® Fabric Based Breathable Housewrap - Performance Specifications

- Exceeds requirements for all major building codes, including: ICC-AC38

- Outperforms the competition with its combination of Air Penetration Resistance, Water Penetration Resistance and range of available Moisture Vapor Transmission Rates and Drainage Plane properties

- Tensile strength, according to ASTM D-882 testing procedure, is >30lbs. /inch MD, 30lbs. /inch CD

- Passes ASTM D-779 test for water resistance. AATCC127 water resistance > 250cm

- Meets Air Barrier specifications and passes ASTM E2178

- Meets Class A Flame Spread according to ASTM E-84 testing procedure

- Rated to withstand UV exposure for 120 Days (4 months)

CLAF® Fabric Based Roofing Composites

CLAF® Fabrics have the strength, UV resistance and breathability to enhance your roofing products.

- Low elongation increases durability and reduces consequences of tears

- Flat profile protects breathable films

- Coextruded strands allow introduction in thermal calendering section of non-wovens lines

- ANCI, Inc. Converting Services can also develop custom composites by utilizing our expertise with various internal lamination techniques

- Our Converting Services division manufactures a wide variety of composites using non-wovens, breathable and non-breathable films and reinforcement materials

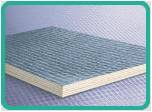

CLAF® Based Reinforced Radiant Barriers

- Radiant Barrier manufacturers rely on CLAF® Fabric to reinforce foil/film/paper (or plastic) composites

- CLAF® Fabric's flat strands, structure and high orientation provide a smooth laminating surface and increased tensile, tear and puncture resistance