Carbon Roll

Overview

Carbon rolls are used in broad range of fields, including prints, film, papers, and liquid crystal displays.

In recent years, with the increase in size (width) and speed of manufacturing systems, carbon roll demand is growing.

By optimally combining PAN-type and pitch-type carbon fibers, we can present designs that match our customers' needs.

Features

- 1.Lighter weight --- Improved productivity and safety

- While operating efficiency and roll replacement workability are greatly improved, both of productivity and safety can be achieved.

- 2.Lower inertia force --- Attainment high-speed rotation and reduced running costs

- While high rotational control is maintained, stable transport of base material can be achieved. And the reduced drive energy helps to reduce running costs.

- 3.High rigidity --- Low deflection and improved product quality

- By reducing deflection, stable transport of base material can be achieved. It contributes to improve product quality.

Design

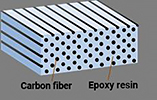

Carbon rolls are made of carbon fiber reinforced plastic (CFRP). CFRP is a composite material that consists of carbon fibers, which provide material strength, and resin (epoxy resin), its base material.

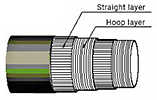

With respect to a uniform load distribution, the carbon roll structure is designed to minimize deflection by distributing high-elasticity carbon fibers in the longitudinal direction, where bending moment is large.

Thanks to our technical expertise (based on years of experience and an extensive record of performance) and analytical skills (employing the finite element method), we can offer optimal designs.

Scope of Production

ENEOS can propose optimal solutions according to our customers' request.

| Item | Supported Scope | |

|---|---|---|

| Size (excluding rubber) | Outside diameter | φ30 - 350mm |

| Length | Max 8,000mmL | |

| Thickness | 5 - 20mm | |

| Surface treatment | Rubber | NBR, CR, silicone, urethane, etc. |

| Metal | Hard chrome plating | |

| Shape | With shaft type (SUS, iron) / Tendency type / Without shaft type | |

| Axial modulus | Max 30,000kgf/mm2 | |

Product Performance

Comparison of Roll Shell Materials

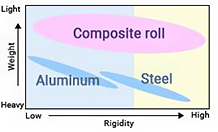

Up to now, roll shell material has generally been steel when rigidity was required, and aluminum when light weight was the aim.

From high rigidity to low rigidity, carbon (composite) rolls have been designed with a large amount of freedom.

Also, since they are lightweight, they are widely used as roll shell material, regardless of their rigidity.

Comparative Example of Metal Roll and Carbon Roll

The performance of carbon rolls varies according to the design.

For example, the performance of a metal roll and carbon roll of the same size and rigidity is compared below.

- Example 1 : Comparison with steel roll --- Lighter weight

- Example 2 : Comparison with aluminum roll --- Thinner thickness

Comparison of steel and aluminum performance (φ100×1700L, same rigidity)

| Item | Example 1 | Example 2 | |||

|---|---|---|---|---|---|

| Steel | Carbon roll | Aluminum | Carbon roll | ||

| Outside diameter | mmφ | 100 | 100 | ||

| Surface length | mm | 1700 | 1700 | ||

| Shell thickness | mm | 7.0 | 7.5 | 7.0 | 5.0 |

| Shell weight (metal ratio) | kg | 27.3(100) | 6.3(23) | 9.4(100) | 4.0(43) |

| Self-weight deflection | mm | 0.038 | 0.009 | 0.038 | 0.016 |

| Moment of inertia (metal ratio) | 105N・mm2 | 24(100) | 3.6(44) | 8.2(100) | 5.4(23) |

| Critical speed | rpm | 5,500 | 8,700 | 5,500 | 12,400 |

Application Examples

Our carbon rolls have been used in a broad range of fields, including print, film, and liquid crystal displays.

- 1.Print field

- Rubber rolls for rotary presses are used by newspaper publishers throughout Japan, as they lighten the workload in the production process and greatly contribute to improved productivity.

- 2.Film field

- On optical, high-performance, and thin-film production lines, carbon rolls have been used as guide rolls and nip rolls, thanks to their low-inertia, low-deflection features. On film slitter/winder lines, carbon rolls have been used as touch rolls, not only because of their low inertia and low deflection but their high-speed rotation performance.

- 3.Liquid crystal display field

- Thanks to lower deflection by high rigidity, carbon rolls contribute stable transport of base material and improved productivity.